DYNOGRAPH

Our inertial dynamometer measures rear wheel horsepower, which can be calibrated to different standards, the most common being DIN or SAE. It will be possible to convert our chassis dyno to an engine dyno, but at the moment this is limited to kart engines, so we can perform controlled “run in” on these engines by prior appointment, or “in kart” on request.

Our inertial roller is sunk into the floor for a lower deck height, which makes for easier loading of motorcycles, and also allows for a larger roller diameter and higher inertial loading than others. This customised installation further simplifies the dyno room operations by reducing floor based clutter to a minimum, and our transparency extends to giving a large viewing window for our clients, so they can watch their vehicle being processed from start to finish.

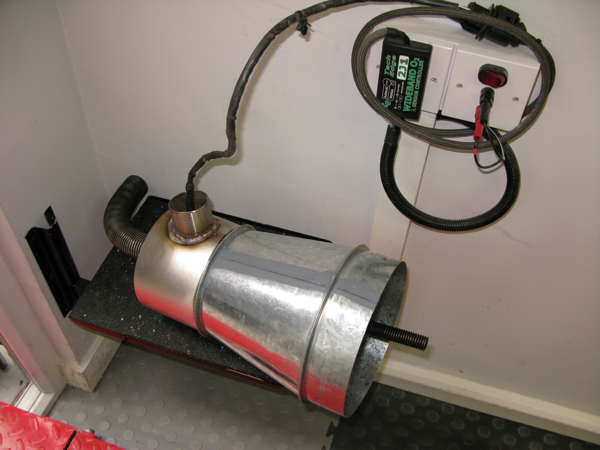

The dyno room also offers an integrated O2 sensor and extraction facility, so real time lambda levels can be monitored, either as part of a dyno run, or as a standalone device in conjunction with it’s own software or others supplied.

Later we hope to offer bespoke engine development to multicylinder motorcycle engines using an engine test cell environment within our facilities. This capability is under continuing development and is expected to be completed in early 2013.